Magnets

Ceramic magnets are the magnets to use. They are

large enough to be easy to handle and in the correct strength are unlikely to damage anything.

Ceramic magnets are available in a large variety of sizes and strengths. Ceramic magnets are the magnets to use. They are

large enough to be easy to handle and in the correct strength are unlikely to damage anything.

Ceramic magnets are available in a large variety of sizes and strengths.

Good ceramic magnets are not weak

— particularly

latch-type magnets with steel plates attached. The plates are poles

that greatly increase the power of the magnet.

If the plates are removable then the magnet is

dual-power.

The two drawbacks of ceramic magnets:

-

They can be broken if you're not careful with

them. Dropping or carelessly tossing them around the board is a good

way to crack magnets. Don't over-tighten hardware used to attach

magnets.

-

If magnets and loose bits of metal (hardware,

drill bits, pins,

razors, etc.) are not kept away from each other you'll find all those

bits every time you pick up a magnet. This problem doesn't go away

with other types of magnets. An organized, uncluttered shop

is a good thing no matter what building system is used.

Rare-earth magnets are much too powerful

for model-building tasks. At the correct strength they are very small and

difficult to manipulate or remove. They concentrate too much force in a small

area. Think about trying to separate small, powerfully-attracted disks and

squares that are crushing your balsa.

Rubber magnets (craft and refrigerator) are

very weak but may have their uses — small stick models maybe. I have

some round craft magnets but haven't found a use for them. The problem

with them isn't their strength but that they are cheaply made. The

disks are obviously punched from sheet and have a tapered edge so they can't

be counted on to hold anything square.

Electromagnets - All the magnets must be in

place exactly where you want them when you turn on the juice. All the

magnets let go at the same time. This system won't work well for us.

The

magnet that I have found most useful is a latch magnet. These can

usually be found anywhere cabinetry supplies are sold, but will be expensive

if you buy them that way.

I

purchase part number CA41LWH from

The Magnet Source. Each of these magnets is advertised to have 12 lbs of

holding power with the metal plates attached. I didn't measure the

actual pull, but they stay in place - even when bending 3/8" square spruce.

The magnets are much less powerful without the plates, but are very useful

in lighter duty applications.

Forty magnets will not get you very far when you get deeper into using the

system.

If you're serious about building then I suggest you start with 100 magnets.

If you make your own fixtures you'll need 200 magnets. A set of 20 fixtures uses 80 magnets.

When you start

building a wing using 4 or more magnets to properly align each rib plus

magnets to hold the spars, leading and trailing edges you'll understand why

you need a lot of magnets.

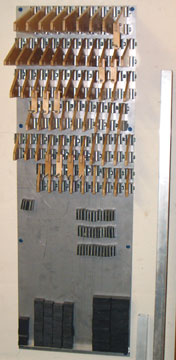

A storage board (right) is a very good idea. It stores your magnetic tools where they stay

together and are not attracting loose metal items in your shop.

Mine is mounted on a wall where it's accessible but out of the way.

|

![]()