What to Purchase Next

The table saw shown

to the left is

the Microlux Tilting Arbor table saw sold by MicroMark.

It's the same saw as the

Proxxon FKS/E Deluxe Small Scale Table Saw. The table saw shown

to the left is

the Microlux Tilting Arbor table saw sold by MicroMark.

It's the same saw as the

Proxxon FKS/E Deluxe Small Scale Table Saw.

It's a smooth running

saw and I've loved it since the first time I used it. If it lasts just a

couple more years then it will pay for itself in the money I've saved buying

stick wood. I suspect it will last for quite some time

— it's a quality

unit.

I purchased several blades at the same time that I purchased the saw because I

was confident that the blades I chose would be useful. I was right about

that. The thin, fine blade (I don't remember the exact number of teeth) cuts

very cleanly to the point that little or no sanding is required. However,

it will wander on thicker stock due to its flexible nature.

The black fence in front of the saw is the Accurizer II fence sold by

Micro-Mark (catalog# 80467). When I saw it in the

catalog, I

was concerned may be a useless gadget. It is actually an

excellent device and I recommend it as well. It allows for

very precise control over the width of the cut. Although it is over $50, I

feel it was money well spent.

The only thing I don't like about this saw is that it's difficult to clamp a

longer fence to for cutting long sheets of wood. Using the stock fence or

the micro-adjustment fence causes the wood to cut with a large bow because the

fence just isn't long enough. I've managed to find a

way to attach a long section of extruded aluminum to the saw, but it is precarious at best.

At some point I'll build some type of support to put behind the

saw for longer pieces of stock. I'll probably just build a mini saw-horse

or similar. By the way, I use the cut-off scraps that are too small for

anything else to mix epoxy. Also see

A really

tedious task is fitting the sticks in a built-up structure. Many of the

pieces have a double-bevel at each end. If you've ever built up a fuselage

from square balsa stock then you've probably discarded a lot of pieces

that ended up being too short by the time you got the bevels right. A really

tedious task is fitting the sticks in a built-up structure. Many of the

pieces have a double-bevel at each end. If you've ever built up a fuselage

from square balsa stock then you've probably discarded a lot of pieces

that ended up being too short by the time you got the bevels right.

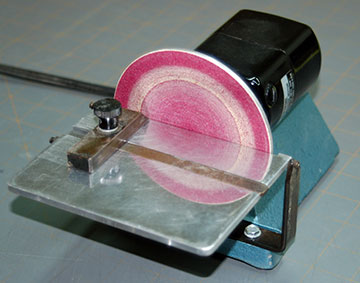

I bought a disk sander

that has greatly simplified this task. I lay

the stock over the plan and mark it with a single-edge razor blade. Then I cut it

slightly oversize. The disk sander brings it to its final size and the

joints fit much better. This is another tool that I recommend if you can

afford it. I bought the Jarmac unit and am happy with it. There are

units made by other manufacturers as well.

The Jarmac is a small unit — perfect for small parts. A 10" disk

sander would be

awesome too.

I purchased the Jarmac foot operated speed control at the same time. I'm not

happy with that component. It works fine, but it is too light and it

slides all over the floor. I

invariably kick it further under the table when trying to find it with my foot which means I have to interrupt my

work to retrieve it. A buddy of mine purchased the Dremel speed control which

is a heavier unit. So I might just buy one more thing from Dremel before I

boycott them.

This is a small unit and I have been wanting a larger 10" sander as well.

This sander can handle parts about 1" wide and then it starts doing funny things

due to significant difference in sanding rate from the center of the disk to

perimeter. In other words, I can't use it to sand the edges of formers,

but it's perfect for what I purchased it for — fitting sticks.

Also see

|

![]()