|

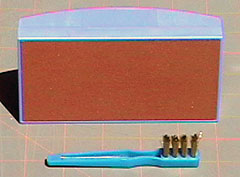

Sup-R

Sanders are plastic blocks having a tungsten carbide sanding surface. The

blocks are color-coded (fine, medium and coarse) for easy identification.

Other than the grit, the blocks are identical in size and shape. Sup-R

Sanders are plastic blocks having a tungsten carbide sanding surface. The

blocks are color-coded (fine, medium and coarse) for easy identification.

Other than the grit, the blocks are identical in size and shape.

Each block is approximately 2-3/4" wide x 5-1/4" long. The tungsten

carbide sanding surface is permanently adhered to the block and is smaller than

the outside dimension all the way around by approximately 1/16"

The blocks are comprised of top and bottom pieces that separate to store the

included brass wire brush used to clean particles from the block.

Because the sanding surface is made from tungsten it should last a very long

time. The tool carries a lifetime warranty, but I do not know if that

warranty applies to the surface wearing out or just to defects. The

manufacturer's recommended list price is $13.60 each.

I used these blocks as much as possible while working on my

DoodleBug 330

project — a profile fuselage, control-line

stunter. In addition to various grades of balsa, I used the blocks to

sand maple motor mounts, birch plywood, soft aluminum and dural aluminum.

I like the size of the block, but would prefer them to be a little

heavier. It would not be difficult to add weight to the blocks by

pouring leftover epoxy in the bottom.

Sup-R Sanders excel in two places that make them worth their weight in gold

— sanding plywood and aluminum. Normal

sandpaper wears out very quickly when edge-sanding plywood. Because I glue

paper to blocks, I always dread it when I have to sand plywood task because

doing so means the paper will need to be changed

— sometimes more than once before the job is finished.

I used these blocks for that same task and they were not phased a bit.

That means my sandpaper blocks will last a lot longer now.

All three blocks remove stock quickly when sanding balsa. The coarse

block tears away balsa at an incredibly fast rate which will make it excellent

for roughing in wing tips blocks and similar tasks. I would say that the

coarse block falls somewhere between a wood rasp and 120 grit paper.

Roughly it is probably about equivalent to 60 or 80 grit paper. All three blocks remove stock quickly when sanding balsa. The coarse

block tears away balsa at an incredibly fast rate which will make it excellent

for roughing in wing tips blocks and similar tasks. I would say that the

coarse block falls somewhere between a wood rasp and 120 grit paper.

Roughly it is probably about equivalent to 60 or 80 grit paper.

I chose to cut the landing gear from dural aluminum plate. The edges of

the gear were fairly ragged after cutting them with my scroll saw. I have

never had good success using metal files on aluminum. They clog up quickly

with galled aluminum and I generally find files awkward to work with.

These blocks did not clog or dull and made short work of the task. The

Sup-R Sanders felt much more comfortable than metal files and were easier for me

to control.

The

blocks have only two short-comings. The first is that the blocks seem too

flexible. They are stiff enough to remain flat on softer woods because less

pressure is applied while sanding. The

blocks have only two short-comings. The first is that the blocks seem too

flexible. They are stiff enough to remain flat on softer woods because less

pressure is applied while sanding.

I have not actually tried to sand a hardwood plank flat with any of these

blocks, so it may not actually be a problem. However, it is something that

I would pay attention to until I was more confident in the block.

A thicker bottom would ensure the block could not flex. I would like it to

be at least 1/4” and preferably 1/2” thick.

The second item is that the blocks can not sand all the way into a corner

because the tungsten pads are slightly smaller than the bottom of the block.

Kentool does not indicate the grit equivalency of the blocks which would be

nice, but is not really necessary. The fine grit would actually be

considered medium to coarse on soft balsa wood. Therefore, Sup-R sanders

can replace coarse and some medium blocks, but fine sandpaper blocks will still

be necessary.

Overall I like these tools and recommend them. They are a welcome

addition to my sanding tools and will save me a great deal of time and money

from replacing sandpaper.

|

![]()