|

Always unplug the saw before you remove or change a blade!

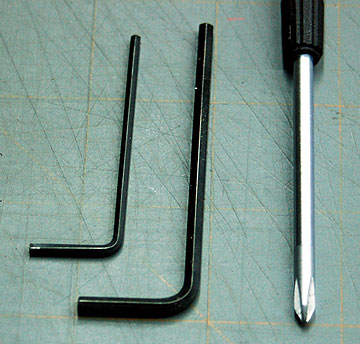

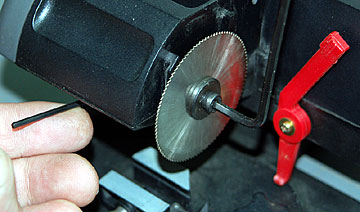

Changing the

blade in this tool is very fast and simple. These are the only tools

needed to change the blade. |

|

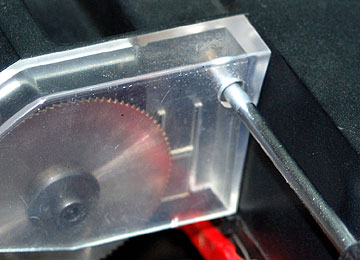

Again, be sure the saw is unplugged

before you attempt to change or remove a blade.

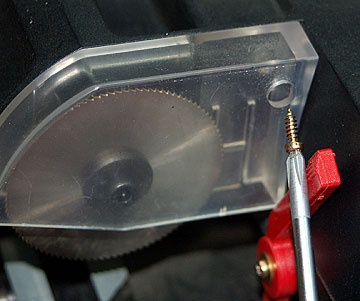

Use the small Phillips screwdriver to

remove the sheet metal

screw that retains the

protective blade cover. If the screw falls off the end of the screwdriver

it will land on the base of the tool where it is easily

retrieved.

Removing and

replacing this screw is easiest to accomplish by moving the safety lever

out of the way. |

|

This is a relatively

small screw and is metric so donít lose it. |

|

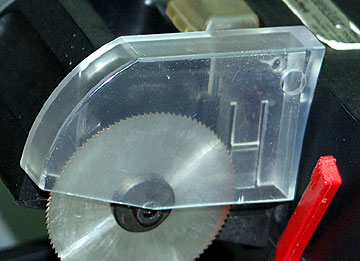

Slide the

protective blade cover straight up to remove it. |

|

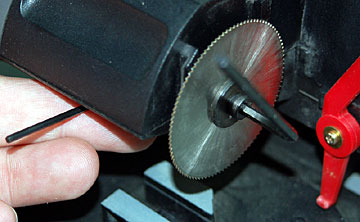

There is a small hole near the

center of the underside of the saw head.

Insert the

small hex key into this hole. Turn the saw blade slowly by hand until

the hex key engages the drive shaft which will prevent the blade

from turning when you loosen or tighten the blade retaining bolt. |

|

When the hex key has

engaged the shaft, use the larger hex key to remove the blade retaining

bolt. |

|

The blade, blade

washer and retaining screw. Again, this hardware is metric. Donít lose

it. That doesn't mean to say that it's ok to lose hardware that's

not metric. The point being, don't lose parts to your stuff when you

take it apart. |

|

The drive washer

has a shoulder on both sides. This is important to note because all

blades and cut-off wheels that can be used with this saw are not the same

thickness. |

|

This side of the drive washer has a taller

shoulder and should be used for thicker blades.

When mounting a

blade or cut-off wheel, always be sure that the shoulder does not come all

the way through the blade which will prevent the blade washer from tightening the saw blade safely. |

|

This side of the

drive washer has a shorter shoulder and is for thinner blades. |

|

After determining the proper side of the drive

washer to use, put the drive washer back on the drive shaft.

Place the blade on the

drive washer. Note the direction of the blade teeth.

The teeth should throw saw dust toward the back of the

saw away from you. |

|

Ensure the blade remains on the drive

washer with the shoulder positively engaged in the center hole of the blade.

Place the blade

washer over the bolt. Hand thread the bolt in place while holding

the blade. |

|

Use the small hex key again to engage the

drive shaft through the bottom of the saw head.

Tighten the blade

securely. |

|

Slide the protective

blade cover back into place. Be sure it is fully seated so that the hole

for the retaining screw is aligned with the hole in the saw head. |

|

The best way to replace this screw is to

use a Phillips screwdriver that fits the screw head well enough that the

screw doesnít fall off easily.

Itís also easiest to replace the screw with

the safety lever moved down and out of the way.

Thread the screw and driver through the

outer hole and start the screw in the inner hole. If youíre as

uncoordinated as I am you may drop the screw a half dozen times before youíre successful.

You can hold the

saw over you head sideways so you can put the screw straight into place,

but thatís not as much fun as all the swearing you get to do after youíve

dropped it for the seventh time. |

|

Thread the safety cover retaining screw

until it is just snug. Donít over-tighten this screw or you will strip

the plastic in the saw head.

The saw is now

fully assembled and ready to use. |

![]()