|

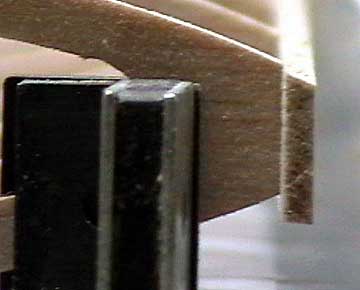

This is where I goofed. These balsa blocks

are about 3/4" square and will be the wing bolt support blocks.

I

should have glued these in place before leaving the wing for the night

because I have to wait for them to dry before I can sand the trailing

edge to receive sheeting. Like I said, it is not a big deal.

Here they

are being test fit. They should fill the entire area (top to

bottom) to provide the best support for the nylon wing bolts. |

|

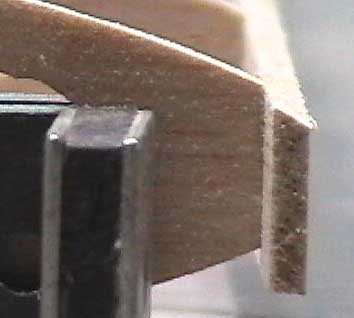

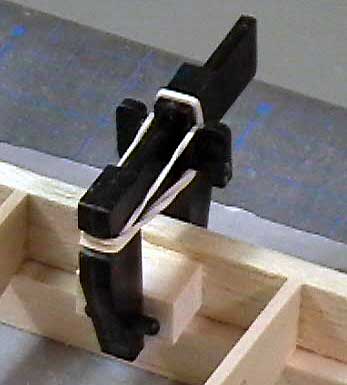

The wing bolt support blocks glued and

clamped in place. This step took 5

minutes

Elapsed time 55 minutes |

|

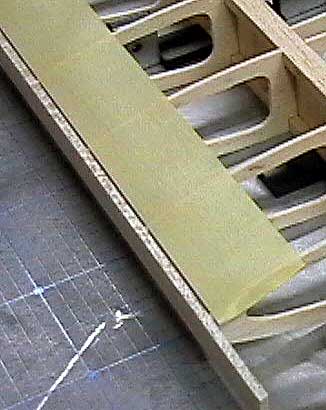

The sub-leading edge must be faired into

the

ribs

before sheeting the wing. This applies to wings that have leading

edge sheeting (D-Tube) as well. The only tool necessary is a sanding block.

I use

a razor plane to bring the sub-leading edge roughly to shape. However, it is easy to

gouge the ribs if you are not careful.

Proceed slowly and

especially watch the angle of the plane. The sole of the plane

should be a tangent to the forward most part of the rib. |

|

It is difficult to see here, but the

sub-leading edge is still slightly higher than the ribs. Man I wish

I had a decent digital camera. This

is where I stopped planing the sub-leading edge in preparation for final

sanding. |

|

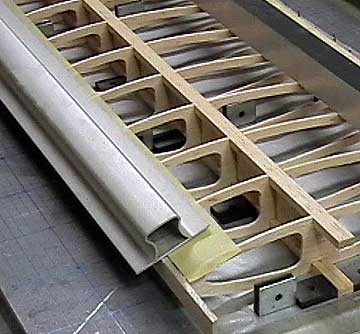

I use masking tape to protect the ribs while

sanding the sub-leading edge. The tape will prevent the part from

completely fairing in to ribs. When the sanding

block starts cutting through the tape at the forward portion of the rib,

I remove the tape and carefully finish sand. |

|

The ribs are not well supported side to

side. Anyone who has attempted to sand back and forth spanwise has

experienced the sanding block "chattering" which is not a good thing.

Instead of sanding spanwise, sand from back to front, but do not go back and

forth. Lift the sanding block, place it back on the masking tape

covered ribs and pull the block forward over the sub-leading edge while following the contour of the rib.

If you start cutting through the tape

then replace it unless the tape is being cut through directly behind the

sub-leading edge. In that case, remove the tape and finish sanding

while

being careful not to remove material from the ribs. |

|

Here is the sub-leading edge after finish sanding. This

step took 17 minutes

Elapsed time 1 hour 12 minutes |

|

At this point I decided the wing bolt support blocks had

dried long enough. Titebond grabs in about 20 minutes. If this were

wing sheeting,

spars or something that could cause the wing to

warp then I would have

left it to dry thoroughly before proceeding. I planed down the

trailing edge and the blocks at the same time and then sanded in

the same manner as the sub-leading edge.

Again, masking tape protects the ribs.

This step took 14 minutes

Elapsed time 1 hour 26 minutes |

|

The trailing edge is only 1/4" deep.

There is not a lot of material there to hold the

hinges

securely.

Lightweight blocks are glued in front of the trailing

edge to give additional support to the hinges.

Determine the size of the block by

measuring the hinge and subtracting the thickness of the trailing edge.

Add a little bit onto that so the hinge is fully enclosed in wood. |

|

I eye-balled the hinge support

blocks locations. Their placement is not critical as long as they are

mostly centered top to bottom.

This wing has separate

flaps and

ailerons. I will be using three hinges in each (twelve hinges

total).

This step took 9 minutes

Elapsed time 1 hour 35 minutes |

|

Draw reference lines to represent the hinge block

locations. The hinge slots or holes, depending on the type of

hinges used, are not cut until after the wing is sheeted and the blocks

are no longer visible.

I will be using Robart Hinge Points.

I used to rely on my memory for things like this. It didn't take long

for me to discover that my memory

isn't all that great.

Now I take notes or mark things so I can

remember what I did.

I did not time this step. Let's say

two minutes just for fun.

|

![]()