|

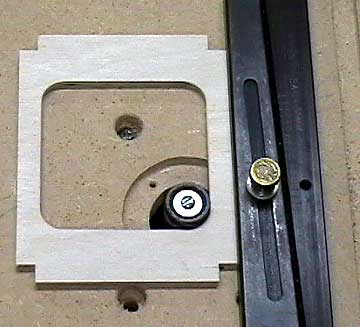

Interior cut outs should always have radiused

corners. They look better and are stronger than sharp corners. I use a 1/2" sanding

drum on a Dremel to make the corners.

First mark the center of the corners and drill

a hole smaller than the finished radius. I normally use a 3/8" bit

in a drill press to get started.

Next, use a hobby knife, scroll saw or

jeweler's saw to finish the cut-out.

Finally sand the inside to smooth it out

and use a Dremel or a dowel with sandpaper wrapped around it to finish the

corner.

Here I am showing my anal-retentive nature

by using a sanding drum on my Dremel in my

router table to clean up the inside cut-out.

|

|

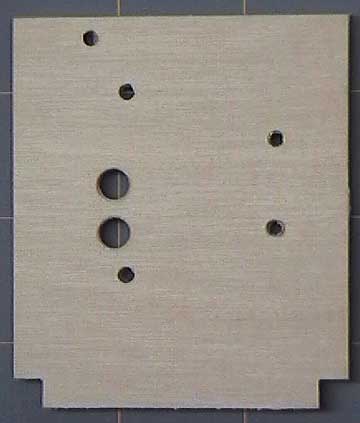

The front face of the

firewall. It has

been drilled for the

engine mount, fuel lines and

throttle linkage.

This aircraft will have a

tail wheel so there is no

nose gear mount.

Notice that the

fuel line holes have been

chamfered using a counter-sink to soften the edge and help prevent the

plywood from cutting the fuel line. |

|

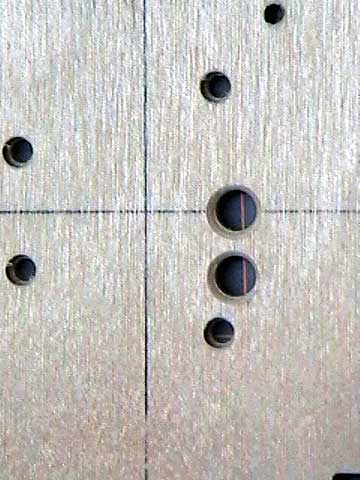

The rear face of the firewall. Again,

notice the chamfered fuel line holes.

Also note that the holes for the engine mount

screws have been enlarged slightly on the rear face to receive the blind

nuts. |

|

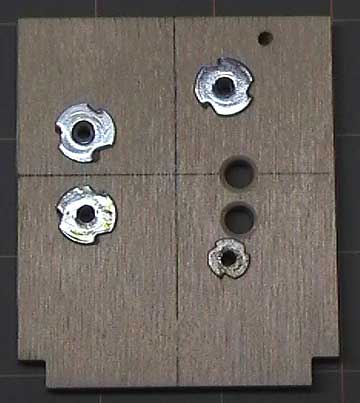

The blind nuts have been

tapped in place with a small hammer. The smaller blind nut is made

by a different manufacturer but they all have the same thread (6-32).

I used a small blind nut so

that I would not have to grind away part of the flange to prevent it

from blocking the fuel line holes. However, if you run into this

problem you can grind away part of the flange with a Dremel. The

blind nut will still be strong enough.

|

|

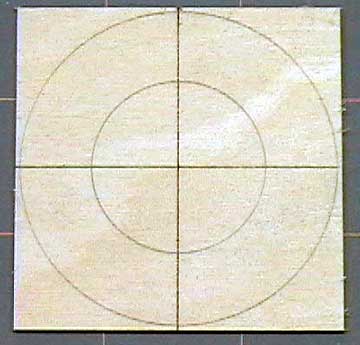

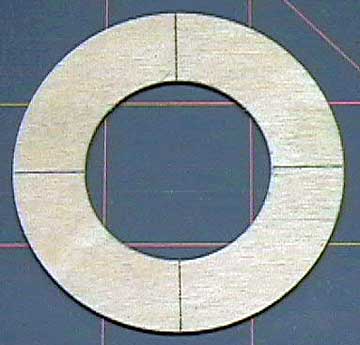

It is easy to make a perfect nose ring.

Start by selecting a piece of plywood of appropriate thickness.

Draw the centerlines and the outer diameter of the

spinner.

The diameter of the nose ring should be

slightly larger than that of the spinner assuming the fuselage tapers

normally. Add about 1/32" to the radius of the spinner before

drawing the circle.

The inner circle only needs to be large

enough to pass the thrust washer with a little margin for error. |

|

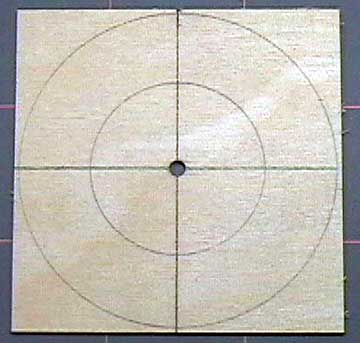

Drill a 1/8" hole in the center of the

former. |

|

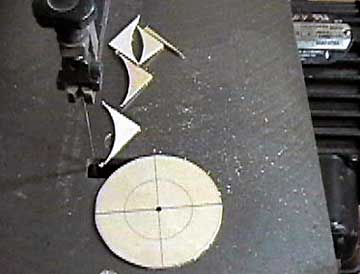

Trim off most of the excess using whatever

method you like. Leave enough material so the former can be sanded

to final shape. |

|

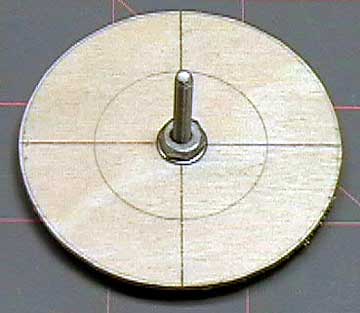

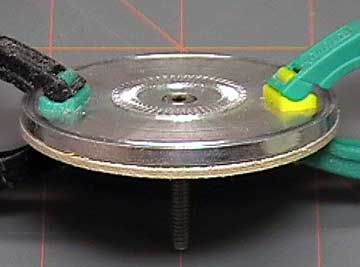

If you have a drill or a drill press you can

make final shaping really easy. Thread a 6-32 bolt through the former with a washer on each side.

Thread a hex nut on and tighten it securely.

Do not chuck this assembly into your

moto-tool unless you want to learn how cheap the bearings in these tools

really are. They will not last long with an unbalanced load such as

this. |

|

Chuck the assembly in your drill or drill

press. Use a sanding block to take the former down to the line.

Notice that the bolt is threaded through so the lines are visible.

Do not continuously press the block against

the former. Instead, push the block up to the former until it just

touches. Then hold the block still until the high spots are

knocked off. Keep doing this until the former is to the line.

Turn off the drill and check the spinner

backplate against the former. Keep sanding until they match well.

You can also sand a slight taper into the

former by tilting the block so that the former matches the taper of the

fuselage. |

|

I leave the ring slightly over-size so I

can finish sand it after it is glued on the fuselage. Here you can

see that the former is a hair larger than the spinner backplate. |

|

Cut out the inside of the nose ring when you are satisfied that the outside edge

is correct. |

|

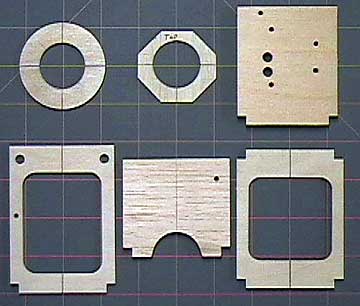

The complete set of formers from the nose rearward shown in order from

left to right, top to bottom.

The center former in the bottom row goes in

the center of the radio compartment. The cut-out at the bottom is

to pass wires from the

servo compartment to the

receiver/battery

compartment.

Note the former at the bottom left. This former is located at the

leading edge of the wing. The holes for the wing dowels are

already drilled to simplify

mounting the wing.

Note that the dowel holes are as far apart as possible. The

farther apart these holes are, the more stable the wing mount will be. |

![]()