|

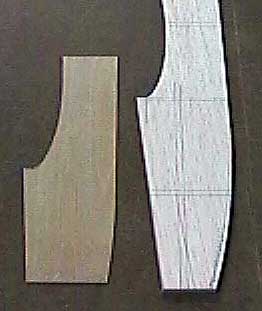

The forward fuselage

doubler is cut from 1/64"

plywood. The wing saddle area

on the doubler is left oversize and will be sanded to

final shape after the doubler is glued to the fuselage side.

Epoxy glue is used to minimize the tendency to

warp. Also, water-based glues can take a long time to dry when used

for laminating.

After the doubler was positioned, a piece

of waxed paper was placed over it and then a great deal of weight was

placed over the doubler until the glue cured.

|

|

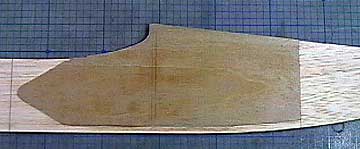

The

wing saddle area has been shaped and

former positions have been transferred to the inside of the doubler. |

|

A straight-edge is used to align the

longerons inside the fuselage. This will help with alignment later

as well as minimize sanding. |

|

Vertical supports are used

to prevent the fuselage sides from

cupping. They add a lot of

strength across the grain and their weight is negligible.

A triangle is used to ensure

they are square to the bottom of the fuselage. |

|

After gluing the longerons in place they are

weighted down to dry. Weight is

added a second time after the vertical pieces are added. |

|

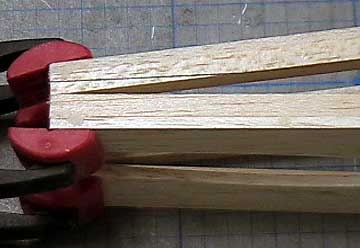

The fuselage sides are taped back together

and block sanded to an exact match. Because of the care taken

during assembly, only a light sanding was needed to remove excess glue.

I used my long sanding block used for

truing

edges of sheets.

Instead of moving the sanding block over the work, I did just the

opposite after clamping the block to the workbench. |

|

The fuselage side is

jigged up on the board

so that the bevel can be marked at the tail post to bring the fuselage

sides together. The first step is

to determine how thick the fuselage should be at the tail and mark half

that measurement on each fuselage side from the outside. In other

words, if the fuselage is to be 1/4" thick at the tail, then measure

1/8"

from the outside and mark the bevel at that point parallel with

the fuselage center-line. In this case the tail post is 3/8" wide,

so each side is 3/16". |

|

The fuselage side is trimmed to the line

shown. The line is drawn on one side only. The sides are

laid next to each other and the line is extended across the inside.

Both sides are sanded up to the line. It does not hurt to put a

piece of appropriate diameter music wire at the tail post to act as a

sanding stop.

Sanding to the bevel is not difficult but

take your time and stop to check your work frequently. If you sand

too much away you can add a shim in between the sides to bring back some

thickness. |

|

The tail end of the fuselage sides after

they have been sanded. |

![]()