|

Before doing anything else, select the wood to

use for the fuselage sides. I like straight-grained wood that is

firm and light. Contest balsa can be pulpy so I generally do not use

it here. This model is receiving a

natural

finish so I also selected pieces that have a nice mottled

appearance and matched the overall tone of the wood. In fact, I

sorted the wood by color first and found that I had five different stacks

by the time I was finished.

I went through each stack until I

found three pieces of wood (sides and top) that matched in color,

grain-pattern, weight and flexibility.

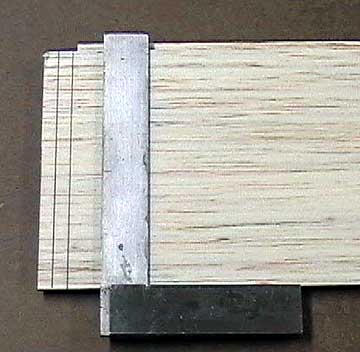

After the two sides each have one

true edge, locate the

reference line. Normally it will be parallel to the trued edge.

In this case I will use the bottom of the fuselage as the reference line

so another line is not necessary. |

|

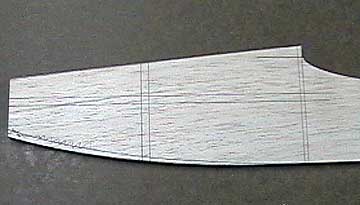

This is one of the original fuselage sides

that was scrapped. I have drawn in the firewall location.

The

thrust line will be 0°

right and 0° down (0°-0°),

so it is perpendicular to the bottom of the fuselage having no right or

down thrust. The new set of

fuselage sides has the

cowl as part of the side so the firewall is

located further back. |

|

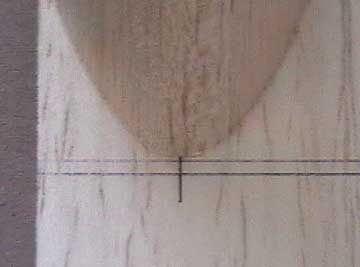

Next I measure back to the

leading edge of the wing. Normally I determine where the leading

edge is by measuring the

fuel tank length and adding 1/2" to 1" to that

measurement.

Measure the

chord of the

wing without the

ailerons and draw the location of the

former aft of the

wing.

Locate the wing centerline.

I normally set up a symmetrical wing with a very slight amount of

positive

incidence. This is because at 0°

the wing has zero lift. When I say a slight amount of positive

incidence, I'm talking about the leading edge being about 1/32" higher

than the trailing edge. In this case, that amounts to a fraction

of one degree. |

|

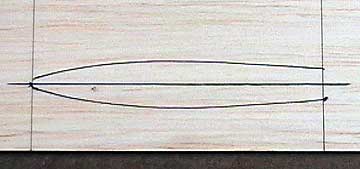

Carefully locate the wing

over the centerline and trace around it.

Now you can see why I have

left the wing tips off. Once the

saddles are cut (and you are sure

you will not be cutting another set of fuselage sides) the tips can be

glued on the wing. |

|

Here you can see the leading edge of the

wing located over the centerline drawn on the fuselage. |

|

Ditto for the

trailing edge of the wing. |

|

The same method was used to locate the

cutout for the

stabilizer which was built up using a method similar to

the wing. |

|

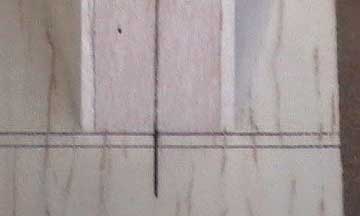

Thin fuselage sides tend to take on a

concave shape (the middle caves in) when the tail is pulled together.

To prevent this I glue vertical support pieces in the

aft end of the

fuselage. The lines drawn here represent the locations of these

supports. Their weight is negligible, but they really help keep the

fuselage sides flat. The fuselage

sides are taped together using double-sided tape. Cut the sides

and sand them carefully to shape while ensuring the edges remain square.

Leave the sides joined and transfer the

former locations to the edges of the sides. These lines are used

to mark the former locations on the fuselage side that has not been

marked. |

|

The fuselage sides are carefully cut out

using straight edges and a scroll or jig saw. Because this model

will receive a natural finish I took extra care cutting the wing and

stabilizer saddles. Using putty and filler will not be an option

so the fit has to be good. I made a

sanding block from a scrap of 3/8" x 1-1/2" x 6" balsa. One of the

faces was gently rounded over and fine sandpaper was used to shape the

saddles after they were initially cut oversize. The wing and

stabilizer were checked against the saddles several times during the

shaping process. |

|

Here you can see the final stabilizer fit.

The excess wood aft of the trailing edge of the stabilizer will be

trimmed

away later. |

|

After the thrust line was initially drawn

it was relocated 1/4" lower to position the engine properly in relation to the fuel tank. |

![]()