|

|

Tips

for Using and Caring for Your Tools

-

Take

care of your tools so you can buy new tools with your money instead of

replacing tools that you already had. Every time you go into your shop

make it a habit to pick a few of your seldom-used tools to maintain.

Dust and oil them or do whatever other maintenance is necessary.

If

you do just a few every time you go in, you will never be faced with a job of

maintaining them all at the same time and it will not even seem like a chore.

Maintain tools that you use frequently as soon as you are finished using

them.

-

Wax your "table" tools such as your

table saw,

scroll

saw and drill press frequently using car wax — especially if the

table is prone to rusting and you

live in a humid climate. The wax will help

the work slide more easily so it is worth the effort even if rust is not an issue.

-

The work we do is very similar to surgical work (although

there shouldn't be much blood involved, right?).

It stands to reason that the medical industry has some very cool items we can

use. The hardest part is finding a place to purchase these tools.

Companies like

Micro-Mark and a few others have gathered items from various

industries and made them available to modelers.

Talk to people who's work your respect if you

have doubts or questions about certain tools. For example, if you want

to get information about

airbrushes, then ask another modeler who does good

airbrush work. Avoid "experts" who's work does not back up their words.

Look for ways that will allow you to work with both

hands free. If you are holding the work in one hand and the tool in

the other, it can be difficult to have good control over what you are

doing. For example, to sand the leading edge of a wing, place the

wing on your

workbench so that it stands on the trailing edge.

Use

heavy tool boxes or bricks to hold the wing in place using some type of

padding (scraps of foam rubber, etc.) between the toolbox and the wing.

Now you can use both hands to guide a long t-bar

sanding block with less

chance of slipping and damaging the wing. It is not difficult to come

up with similar methods for other tasks.

Go to your local sewing shop and get a can of

sewing machine oil. Use it to lightly coat tools that can rust, lube

O-rings in airbrushes, and lubricate joints in scissors and pliers.

-

I think it is safe to say that we've all bought a

useless gadget tool or two. Hopefully experience will help us recognize

these items as such so we can stay away from them in the future (I am surprised

no one has invented the electronic covering trimmer). Usually the gadget is supposed to stand in for a skill the builder hasn't

developed. There is no substitute for developing your building skills

through learning and doing.

-

If a tool is inexpensive

and it is chromed then it is probably cheap and should be avoided.

Manufacturers chrome cheap tools to disguise poor quality. That does not

mean all chromed tools are poor quality.

-

Buy a good

straight

edge. I have two stainless steel "yardsticks" that are excellent.

They are approximately 3/32" thick, do not knick and will last my lifetime and

then some. They are not rulers as they do not have markings, but they are

excellent for cutting sheeting and covering material. Additionally, they

are very heavy and are great for holding trailing edge sheeting in place, etc. I also purchased a piece of aluminum extrusion from my local building supply.

I think it was 8' feet long, but I do not remember now. I cut a couple feet

off the end leaving me with a 6' straight edge. Because it is aluminum, it

will nick, but it is good for cutting long, straight pieces of covering. I

also clamp it to my table saw so I can cut straight sticks from sheets of wood.

Lastly I purchased a meter stick in

Germany that I have come to

love. It is aluminum with a steel edge. Inset into the back of the

straightedge are two neoprene (O-ring material) ropes that make it non-slip.

It works great for cutting pieces of covering where my other straightedges used

to slip.

-

Use

spray glue to attach 320 Wet or Dry sandpaper to

the back of straight edges to keep them from sliding around, but do not use

these straight-edges to cut plastic covering.

-

Rocket City makes pin clamps that I have used for

years. They are one of those really simple, inexpensive items that do what

they do very well. They are little plastic disks that you push onto a

T-pin. They are a very snug fit and are used to spread out the load when

pinning things in place such as sheeting on a wing. I highly recommend you

try them out.

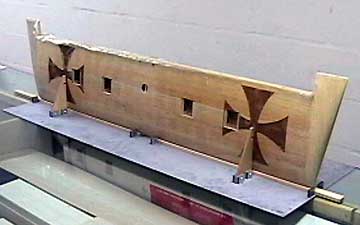

Other things to note in this photo: The trailing

edge is being supported by a scrap piece of trailing edge stock. A heavy

straightedge is holding the trailing edge of the wing down snugly while the

leading edge sheeting is glued on to prevent warps. Other things to note in this photo: The trailing

edge is being supported by a scrap piece of trailing edge stock. A heavy

straightedge is holding the trailing edge of the wing down snugly while the

leading edge sheeting is glued on to prevent warps.Magnets have been

aligned along the leading edge of the wing to keep it straight. At the top

of the photo, all the cap strips have been cut to length and are ready to be

glued in place. I find it faster to prepare them all and then glue them

all rather than cutting and gluing each one individually.

There are four sanding blocks in this photo. My

favorite is in the one made of oak. One side is faced with 1/16" neoprene.

The other side is faced with 1/2" foam rubber and is used to sand compound

curves.

The Tupperware container (top right) is holding all the hardware

for this model. My razor plane (top center) is laying on its side so the

blade does not tear things up and vice-versa. I was using Titebond II to

build this model and I have since decided that I really do not like it.

I have switched back to regular Titebond.

The little film canister in the clear plastic drawer

is great for keeping small parts from sliding under the plastic dividers.

I also use them for miscellaneous small hardware because I once tipped over the

set of drawers and then had to separate all the hardware again.

|

-

It wouldn't be difficult to make your own

clamps. I

spent about five minutes in my shop and found a simple method:

You will need a piece of scrap 1/32"

plywood, a

hand-held hole punch, a number 70 wire drill bit (available from hobby shops,

Micro-Mark or any plastic model supply company), small T-pins and some

CA.

You've probably already figured out how to make them from the list above.

If you use a different size T-pin, you will have to figure out what size bit to

use. You want the disk to be a tight fit over the pin so that when the pin

is pushed into the wood, the disk will apply clamping pressure.

The hole punch I have cuts disks from 1/32" plywood

that are very clean and can be used as is although I would probably use some

fine sandpaper to smooth the edges of the disks. Drill a #70 hole in the

plywood first and then center the hole punch over the hole by eye and punch out

the disk.

Push a T-pin through the hole in the disk and apply some CA to

the area around the hole on the side of the disk that will not be against the

work.

The CA will not stick to the chrome on the T-pin, but

it will keep the hole tight around the pin, otherwise the disk will quickly

become too loose to work as a clamp. Using this method, you could knock

out a hundred or more of these in an hour.

|

|

![]()