|

|

|

|

How

to Install a Fuel Tank in a Model Aircraft

Installing a

fuel tank in a model airplane is a fairly simple process.

It's even easier if you aren't trying to stuff in a tank that barely fits the tank

compartment. Having some space around the tank will allow the tank be

positioned with the least amount of strain on the

fuel lines as well as making insertion less frustrating and tedious.

Whenever you are working with a fuel tank, keep the work area as sterile as

possible. The previous article describes how to clean and assemble the

tank. If you have not washed the tank out, then now is a good time to

disassemble it and clean out the tank and the lines.

Tips

- Ensure that the

engine mount

bolts do not extend beyond the blind nuts into the tank compartment so that they can not puncture the fuel

tank.

- If you are installing the tank in a balsa-dust filled structure, then

chances are some of that dust will make it into the fuel lines. Before

you begin, vacuum the inside of the model or blow the dust out using

compressed air.

|

|

|

|

Background

My Stik 30

was originally built around my O.S. .30 Wankel engine. I took the

engine out after the first day of test flights due to its very high fuel

consumption. It was replaced with a Webra Speed .32 2-stroke

engine.

Exactly a week after completing the model, I rolled a

wing

tip into the ground during a touch-and-go which resulted in a totaled

fuselage.

The new fuselage was not to set up for the Wankel. The Webra had

unresolved idle and transition problems so it

was replaced with an O.S. .46.

The plane was already nose-heavy with the Wankel and the Webra. The .46

made the problem even worse. By the time the

Center of Gravity was where I like it, My Stik 30 flew like a dog due to

massive amounts of lead in the tail.

The only way to save this plane was a major weight-reduction surgery

— nearly

10 ounces of weight was removed from a plane having a

wing

area of approximately 450 in2.

The modification involved installing the Wankel which required the

firewall

and fuel tank to be modified. This article details the tank

installation.

The only reason I bring all this up is so you understand why this firewall

looks like Swiss cheese.

|

|

|

|

Installing the Fuel Tank

|

Because of the shape of the Wankel and the way it mounts,

the fuel lines have to come through the firewall around the outside of the

mount — not through the center. Creative tubing

bends were necessary as well as new holes in the firewall for the fuel

lines to pass through.

I used aluminum tubes on this tank because they bend more easily

than brass.

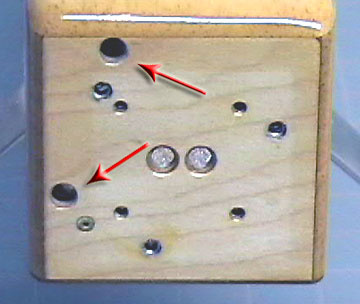

As shown here, the metal tubes are too long and must be trimmed to about 1/2".

Always deburr metal tubing to prevent it from cutting fuel lines

|

|

The arrows point to the new holes for the fuel lines.

The four holes arranged in a square pattern are the engine mounting

holes for the O.S. .46 that was replaced by the Wankel.

The three larger holes are the holes for mounting the Wankel.

All the unused holes were filled with

silicone sealant to prevent

fuel and oil from entering the airframe. |

|

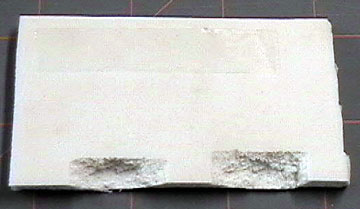

It is a good idea to line the tank compartment with

foam rubber to insulate it from engine vibration and to prevent the tank

from moving. Tank movement can cause the fuel lines

to kink which

will cause many headaches at the field.

This is a good place to use older foam that's kind of ratty looking,

but is still spongy.

|

|

Trying to keep the foam in place while the tank is slid

into the compartment can be a lesson in frustration. Use

double-sided tape or

spray

adhesive to hold the foam in place so you can

concentrate on inserting the tank and not fiddle around with

uncooperative foam that won't stay where you want it.

In this case I tried double-stick tape, but it wouldn't stick inside

the tank compartment. I ended up using spray glue instead. |

|

Here you can see the foam inserted in the tank

compartment. There is a piece above the tank as well. |

|

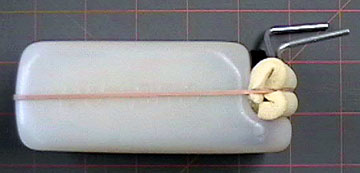

A piece of latex foam rubber is rolled up and rubber banded to

the front of the tank

has a couple useful purposes: It prevents the tank from directly

contacting the firewall which can help prevent it from being punctured

by the engine mounting bolts as well as reduce vibration transmitted to

the tank.

The foam will also help prevent the delicate tubing from being bent

or damaged. |

|

Many people believe that a tank is not sealed if the

metal tubing can rotate in the stopper. That is not true.

The stopper should be snug, but it does not need the life squeezed out

of it. A properly sealed tank will allow the tubing to rotate.

Nevertheless, a tank should always be tested for leaks before installation.

It should also be checked to ensure there is no blockage in the system

by blowing through one of the tubes.

In this case, the ability of the tubing to rotate is very helpful.

I arranged the tubes so they more or less

line up with the holes in the firewall. The tubes were not aligned

properly when this photo was taken, however. |

|

Fuel lines are fed through the firewall and into the

radio compartment. They will be used to pull the tank in place.

Use one hand to guide the tank while using the fuel lines to pull the

tank into place. Every inch or so, pull on each fuel line

individually to ensure that the lines are not kinking inside the tank

compartment.

If you look carefully, you can see that the aluminum tube has been

trimmed to its final length. |

|

The tank in its final position. This rubber band

will break soon. That's ok because now that the tank is in place,

the foam it was holding will remain in position without the help of the

rubber band. |

|

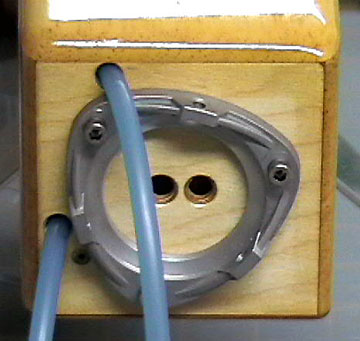

The fuel lines are located outside of the Wankel engine

mount. In the next photo you can see why they could not come

through the center of the mount. |

|

|

|

|

Testing the Installation

Before you go to all the trouble of installing the engine,

throttle linkage,

etc., check to ensure that flow through the fuel lines is not obstructed.

With neither line

connected to the engine, blow through a line. There will be a little

resistance, but not too much. If you can't blow through the tube,

then something is blocked.

You may need to pull the tank back and then tug on the fuel line to remove a

kink. If that doesn't work, then you may need to remove the tank

completely and find out what happened.

If you can't blow through the tank, then the engine will not be able to draw

fuel. It is not a problem that will go away by itself so you may as

well fix it now. Otherwise you will be at the field tinkering with the

installation instead of flying.

|

As you can see, there is no space between Wankel and its

mount for the fuel lines to come through. Fortunately, 2

and 4-Stroke engines usually have enough room between the engine and their mounts

to pull the lines through which simplifies installation. |

|

|

|

|

|

|

|

|

Back to Model Aircraft Engines

Airfield Models Home |

|

|

|

Copyright © 2004 Paul K.

Johnson |

|

|

![]()