Assembling the Fuel Tank

Note: Information contained in the instructions supersedes information presented here.

Before assembling the fuel tank, be sure to review the instructions that came with

it.

It is not difficult to assemble a fuel tank but if it is not

assembled properly you can expect a great deal of

frustration at the field.

All R/C fuel tanks assemble in a similar

manner and these basic philosophies apply to all tanks:

-

Always deburr metal fittings to prevent cuts in the

silicone fuel line.

-

Always set up the feed line

inside the tank so that it is approximately 1/4" from the rear of the

tank. Hold the tank vertically so that it is back-lit to help

you see inside of it.

The feed line should hang straight down. If it clears

the back of the tank by 1/4" then it will be slightly farther away when it is resting on the top

or bottom of the tank. This prevents the fuel from surging into the

line and flooding the engine when throttle is applied (so I'm told).

-

Always disassemble a tank after initial assembly

and wash the tank and fittings out thoroughly to remove metal shavings and other crud. Be

sure to run water through the brass tubing and pick-up line. If you

have an air compressor then blowing some pressurized air into the tank

(without the stopper assembly in place) and through the feed lines will help

remove any particles.

-

There is normally a third hole in the stopper

that is plugged. Don't open this hole unless you plan to use a

three-line fuel system.

Fuel tanks come with brass or aluminum tubes.

The feed line should only extend in to the tank about 1/2". That gives plenty

of tube for the fuel line to grip. If the metal tube is inserted too

far into the tank then it will

inhibit free movement of the feed line.

The vent line should be slowly bent to 90°. I generally make the bend

far enough from the end of the tube so that it is too long. Then I cut

off the excess so that the vent clears the top of the tank by 1/16" to 1/8".

You can either buy a tubing bender or use a variety of methods to keep the

tubing from collapsing when you bend it. Some people fill the tube

with sand or feed a weed-eater line into it while bending.

I

purchased a tubing bender in Germany that works well. The

tube must be pulled while bending to prevent it from collapsing. Soft

tubing can be bent around your thumb if you bend the tubing slowly. The

tube does collapse slightly, but it still passes fuel easily. I

purchased a tubing bender in Germany that works well. The

tube must be pulled while bending to prevent it from collapsing. Soft

tubing can be bent around your thumb if you bend the tubing slowly. The

tube does collapse slightly, but it still passes fuel easily.

Do Not use a

razor saw to cut metal tubing (unless you don't mind ruining the saw).

The two easiest ways to cut the metal tubes is

with a small tubing cutter (K & S) or a

moto-tool with a

cut-off wheel.

To deburr the tubes, turn a counter-sink by hand in the end. The idea

here is to remove the burr inside the tube - not to sharpen the tube.

Use

very fine sandpaper around the outside.

What I normally do is put a cut-off

wheel in my moto tool and then spin the tube at about a 45°

angle against the wheel. Check your work carefully because it

only takes a small cut in the fuel line to make your engine run erratically

and make you pull your hair out.

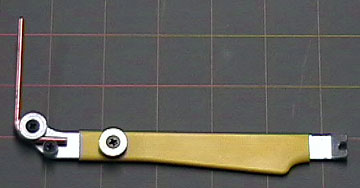

Fuel Tank Stopper Assembly

This is how a stopper assembly should look

when it is assembled. The feed line made of fuel tubing is flexible.

The clunk on the end of the line is heavy

and

ensures that the pick-up is always submerged in fuel.

|

The feed lines should extend about 1/2" from the front of the tank as well.

If the lines do not route in a fairly straight line from the tank through

the firewall, then you may need to

bend the metal tubes in the general direction of the exits on the

firewall. This will

help prevent the fuel lines from kinking in the tank compartment.

The fuel tank is sealed through the use of a

rubber stopper. On the front and back of the stopper are hard plastic

or metal plates. The metal tubes pass through the plates and the

stopper.

A screw goes through the center of the front plate and

stopper and threads into the back plate. When the screw is tightened,

the stopper compresses and expands sealing the tubes and the front of the tank.

You will notice that there is a third hole in most

stoppers that is plugged. Do not use this hole or open it unless you

plan to make a three-line tank. It is easiest to slide the tubes

through the stopper if you spit into the stopper holes first.

A common mistake you can make when assembling

the tank is to over-tighten the stopper bolt. The stopper is

sealed when it bulges and it will not come loose. Just because you can turn the brass

tubes in the stopper holes does not mean they are not sealed. If you over-tighten the stopper it is

very likely that the tank will split and spill fuel all over the inside of

your aircraft.

Testing the Tank for Leaks

Put a fuel line on the vent and another line on the feed. Plug one

line, put the tank under water and blow in the open tube. If you see

air bubbles coming from anywhere in the tank it is not sealed properly.

|

![]()