|

|

Trimming,

Sanding and Axles

From the beginning I intended to trim the gear with my scroll saw because

I knew I would be able to. I could also have used a jeweler's saw or

if the gear is not too much oversize, a disk or belt sander.

I wouldn't even think about a wood plane or a knife due to how difficult

it would be to cut through the laminations and the awkward shape of the

gear. |

|

|

|

Trimming and Sanding the Landing Gear

|

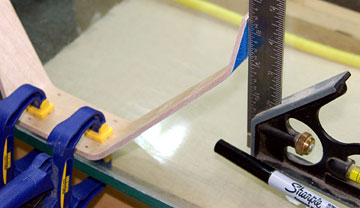

Before laying up the gear I drew the outline on the

underside. As with everything else, aligning the drawing to the

drilled blanks was done by aligning the pin holes (which later became

holes for the mounting screws). |

|

I could only cut to the middle from the end at the front and

back because the area where the gear was being cut was suspended above the

table which is not only dangerous but causes a lot of tear-out. The

gear was suspended because the leg under the saw hit the underside of the

upper arm and the gear couldn't be rotated any farther.

It came out well and now it just needs to be cleaned up. |

|

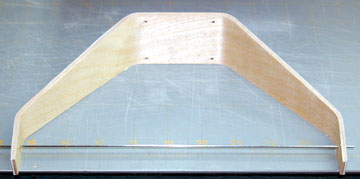

I taped a piece of 120 grit sandpaper to my workbench and

worked the gear over it for until I was happy. Probably about

10-15 minutes all together. |

|

|

|

|

Adding the Axles

|

The second gear I made had one axle hole above the other

because I used marks I made on the underside of the blank before the

lay-up instead of measuring afterward. It wasn't a big

difference but the plane had a noticeable list and it really bothered

me. There wasn't enough material left in the foot of the gear to

correct it.

With the third gear I didn't take any chances. |

|

I drilled the hole 5/64" and then put a 1/16" music wire

through it to ensure I could fix the location if I mis-drilled again.

I need to learn to take more care when measuring and I'd have fewer

do-overs. |

|

The axles have a 1/4" threaded hub. |

|

Which is a little tight in a 1/4" hole so I reamed the

hole to get a slip fit. |

|

All that's left to do is clean up the feet and drill out

the mounting holes. I've considered some additional work on the

gear such as a balsa lamination on the top and bottom with added leading

and trailing edges. The whole thing gets sanded to an airfoil

shape.

I've also considered just a hardwood lamination to the leading edge

to hide the laminations and provide something easier to round over.

Right now it's just a sharp edge from being sanded on my bench.

It will work fine like that but it looks unfinished. |

Whether you fly glow, gas or electric, this is an unfinished wood piece

so fuel, water, dirt, etc. will all get into the grain. I glassed mine

with lightweight cloth and resin but any finish you'd use on a flying model

can be used. |

|

|

|

|

|

|

|

Back to How to Build a

Wood-Composite Landing Gear

Airfield Models Home |

|

|

|

Copyright © 2003-2008 Paul K.

Johnson |

|

![]()