|

A light oil such as sewing machine oil is a good choice for

lubricating and protecting carburetor parts. |

|

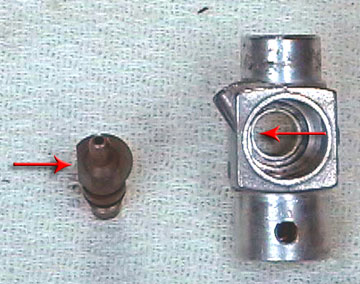

The first item is putting the spray bar back in the

carburetor body. In this case there is a flat on the spray bar that

keys it to the body. The spray bar is oiled well and then pushed

through the body until it keys in place. |

|

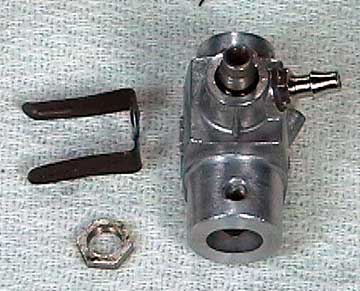

The high-speed needle ratchet and nut are replaced.

This nut also retains the spray bar. I have also threaded the

fuel nipple back on the body.

It is important that you develop a touch for how much to tighten

these items. The carburetor body is soft aluminum and easily

stripped.

Items should be snug but not over tightened. The nipple has a

seal that will spread slightly as the nipple is tightened. You

do not need to completely flatten this seal. Just snug is good. |

|

The low speed needle is threaded back into the carburetor

barrel. This needle engages the spray bar as the barrel is closed.

It is likely the spray bar will be damaged if it is threaded in too far and then the barrel is forced closed.

Just thread it in a

couple turns for now. |

|

The spring is replaced on the barrel. The throttle

stop screw retains the barrel in the carburetor body. |

|

Put the barrel in the body and rotate it so that the slot

in the barrel is toward the back and up and so that you can see straight

through the carb opening (full throttle). Insert the throttle

stop screw. If it does not engage the slot you will know it

because it will jam the carburetor barrel and prevent it from turning.

Be careful with this step so that you don't gouge the barrel.

The stop screw should be threaded in so that it allows the barrel to

fully close. Move the barrel from fully open to fully closed.

Adjust the screw so that the barrel can

move smoothly and doesn't jam at either extreme.

Tighten the lock nut. |

|

The throttle arm and retainer nut are replaced.

With this particular carburetor, the low-speed needle needs to be

threaded in far enough to allow the nut to tighten. Once the

nut was tight, I unscrewed the low-speed needle until it hit the

retainer nut. Again, this is to prevent the needle from damaging

the spray bar.

Next I closed the throttle fully and turned the low-speed needle in

until it just started to feel snug. From there I turned it out 2

full turns. That will be the starting point for the needle when I

run the engine. Undoubtedly this setting will be too rich and require

further adjustment but the engine needs to be run to determine this. |

|

The high-speed needle is replaced. It is threaded

in until it just becomes snug and then turned out 2-1/2 turns.

That will be the starting adjustment for this needle. |

![]()