|

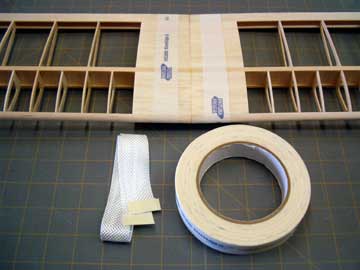

Fiberglass tape is readily available in various widths through the hobby

industry. Use the width recommended

by the kit manufacturer. If in doubt, use wider tape. Wrap the tape around the center to

get a rough measurement. Give yourself some extra length to make it

easier to work with.

A piece of masking tape wrapped around the tape will prevent fraying.

The tape can be cut with scissors. |

|

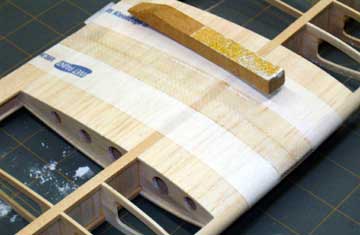

Measure half the width of the tape onto both wing panels.

Wrap low-tack masking tape around the wing. The masking tape

serves two purposes.

- Makes it easy to keep the

fiberglass tape centered.

- Keeps the epoxy from making an ugly, difficult to sand

mess.

|

|

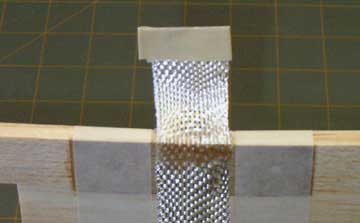

Use thin

cyanoacrylate (CA) to tack the fiberglass to the

trailing edge and only the trailing edge of the wing. Using a

sharp razor blade or a sanding block, remove the excess fiberglass tape. |

|

Wrap the fiberglass tape around the wing, pull it taut

and tack the other end. Do not pull the tape so tight that the

weave is distorted. Trim off the excess.

Note that if the wing has a large amount of dihedral it is sometimes

easier to use individual pieces of tape on the top and bottom of the

wing to prevent wrinkles. |

|

The tape is centered and snug. |

|

Mix up some slow-cure

epoxy and brush it on the tape

using an

acid brush (also called epoxy brushes). I like to use

laminating epoxy because its thin viscosity saturates the cloth faster

and more easily. Regular epoxy glue can be used instead.

Work the epoxy until it fully saturates the cloth. If the glue

doesn't saturate the cloth then the wing joint will be weak which can

result in catastrophic failure of the wing in flight.

If it is too difficult to get the epoxy to saturate the cloth, you

can warm it with a hair dryer which will make the epoxy watery thin.

Never thin epoxy!

Heat will

also cause the epoxy to begin setting up sooner so ensure the entire

tape is coated with epoxy before you warm it.

The wing is shown suspended above the table because both the top and

bottom of the wing were fiberglassed in the same operation.

|

|

Here you can see how the tape should look when the epoxy has properly

penetrated the weave. |

|

Remove the masking tape before the epoxy sets up. |

|

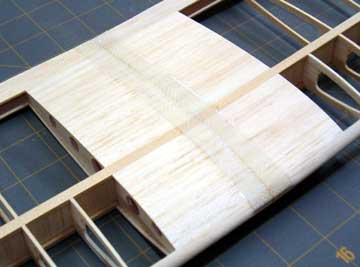

Wrap low-tack masking tape around the wing after the epoxy has fully

cured. The tape is to shield the bare balsa from the coarse

sandpaper. Low tack tape is used because sanding will cause the tape to have a stronger bond. If regular

masking tape is used it can actually damage the bare balsa when the

tape is removed.

Fiberglass tape has a finished edge to prevent it from fraying.

This edge is thicker than the rest of the tape.

Use coarse

sandpaper on a small

sanding block to feather the edge of the

fiberglass. Avoid sanding into the cloth everywhere except the

edge. Especially avoid the center of the underside of the wing

where the most strength is needed and it is easy to sand into the cloth. |

|

A little more sanding is needed if I want the edge of the tape to be

invisible under the covering. This wing is mounted to the

underside of the fuselage and the tape will not be seen.

I spent more time feathering the tape on the underside of the wing which

is visible but stopped here on the top of the wing. |

The wing panels are now permanently joined and properly aligned.

Hopefully this series of articles has demonstrated the importance of joining

the wings properly while also showing that it is a matter of patience and

technique but not a mysterious skill possessed only by expert model

builders.

![]()