|

|

|

|

Model

Aircraft Propellers

Caution! Some propellers have extremely

sharp edges — especially plastic and fiberglass props. For your own safety scrape and sand this edge down. If

you try to flip the propeller by hand you will get a nasty razor cut as your

fingers slide along the back of the blade.

Propellers come in a variety of sizes and styles and are made from five

materials that I know of:

- Wood (Maple, Beech or balsa wood on lightweight rubber powered

models)

- Nylon

- Fiberglass-reinforced Nylon

- Fiberglass

- Carbon Fiber

Wood, Fiberglass and Carbon Fiber props

give the best performance. Nylon props are the least expensive but they

are flexible, cause vibration and rob power.

Do not use nylon propellers!

With the exception of nylon propellers (not to be confused with glass-filled

nylon which are fine), all commercially available propellers work well. If you choose a propeller that the engine can swing in its comfort

zone then it is a matter of personal preference after that. Also see

|

|

|

|

|

Typical Propellers

From top to bottom:

- Master Airscrew fiberglass-filled nylon

- Zinger

- Top Flight Super M (out of production)

- APC fiberglass

- Top Flight Power Point (current style)

- Graupner fiberglass-filled nylon

- A different style Graupner fiberglass/nylon

- Top Flight Super M

All of these propellers are fixed pitch meaning the pitch is not

adjustable. |

Propellers are designated by two numbers: Diameter and Pitch. Thus a 12-6 propeller is 12" in diameter and has 6" of

pitch. Pitch is the distance a propeller will move forward in one

revolution in a perfect fluid (which air is not). Therefore, a 6" pitch

will move forward 6" with each 360° revolution of the propeller.

There are also a variety of styles as you can see in the photo above. For

example, there are wide and narrow blade propellers.

Additionally there are scimitar propellers such as the APC gray

propeller fourth from the top.

The last time I came across numbers regarding

propeller efficiency was over ten years ago. At that time the best propellers were about 80% efficient.

Note that propeller efficiency is not the determining factor of overall flight efficiency.

The propeller should be chosen to match the

aircraft — not the engine. For example,

mounting a racing propeller to a

WWI aircraft will severely limit the model. An early warbird has so much

airframe drag that the propeller will never come close to living up to it's

potential and the model will be a sluggish flyer at best.

By the same token using too slow of a prop (one with low pitch)

on a model intended to go fast may prevent the plane from gaining enough speed to

fly at all.

A lot of pilots make the mistake of finding a propeller that works great on a

certain engine in a certain airplane. From then on they swear by that

propeller on the same engine regardless of the aircraft. If the pilot were

to experiment with other propellers when the engine is in a different aircraft

he would probably find that the current "best" propeller isn't best any more. |

|

|

|

Propeller Properties

Pitch

The easiest way grasp the concept of propeller pitch is

to draw a parallel to the gearing in your car.

Propeller Material

Wood propellers are the lightest and present the smallest load to an

engine assuming all else is equal (diameter, pitch and shape). They are

capable of turning higher RPM than a heavier propeller.

Wooden propellers are also the most easily broken. My opinion is that wood

propellers are the most efficient and best performing in the air. Others

disagree and they may be right because I'm not a good enough pilot to really

have an opinion.

In any case, if you nose over your planes often enough then wood propellers are

probably a poor choice for you.

Fiberglass-filled nylon propellers are the heaviest propellers and also

the most durable. These are a good choice for beginners because they hold

up better than other types to propeller strikes. They are less efficient than

wood or carbon fiber propellers, however.

Carbon Fiber Propellers are very rigid, but extremely expensive. I have

seen carbon fiber propellers only for large engines. They may be available

in smaller sizes in the future.

All of the above propeller materials maintain their shape well under load.

Wood and carbon fiber are best.

Fiberglass-filled nylon propellers are the most flexible of propellers that I

recommend, but not enough to cause significant problems.

Pure

Nylon propellers are always a poor choice unless you crash every time you fly.

If that's the case, then nylon propellers aren't the answer for you. Stamp

collecting is.

Nylon propellers are so flexible that they twist in use which means they are

constantly changing pitch. This flexing also creates a lot of vibration.

The end result is akin to spinning the wheels of your car —

a lot of energy is going to waste. Nylon propellers are just bad.

Don't use them.

Weight

Heavier propellers have the advantage of flywheel action. Flywheel

action will allow a lower, more reliable idle. Note that all

properly designed engines idle reliably anyway, so this is really a moot point.

Another consideration is balancing the aircraft. Personally, I

think the best propeller should be chosen for flight qualities, not for weight,

but if the aircraft is close to being in balance then changing to a propeller of

different weight may put the CG on the money.

Shape

Low RPM engines, such as four-strokes, use wide blade

propellers because four-strokes turn fewer RPM. The lower RPM

means the air that the trailing blade is entering is less disturbed.

Additionally, four-strokes have more torque than two-strokes. Because of

this, a four-stroke can swing a wider propeller efficiently.

High RPM engines, such as two-strokes are more efficient with narrow

blade propellers due to the more disturbed air caused by the higher RPM.

I can't tell the difference between a scimitar blade and any other shape.

I don't even know what the difference in performance is supposed to be so I

can't help you here. |

|

|

|

Determining the Range of Suitable Propellers for an Engine

Engines like to do work. They are happiest

running with a load. An engine can over-rev and be destroyed in short time

if it has too little of a propeller load. If the engine has too much

of a load it will be sluggish and tend to over-heat.

Any engine can swing a wide range of propellers provided the propeller load is within

the engine's

comfort zone

As a rule of thumb each inch subtracted from one property (pitch or diameter)

allows one inch to be added to the other. This theory permits any of the following propellers

to be used on the same generic .40 size

engine:

- 8 x 8

- 9 x 7

- 10 x 6 (propeller recommended by manufacturer)

- 11 x 5

- 12 x 4

This rule breaks down as the propeller size moves farther from the center of the

range.

For example the engine above may not be able to swing a

12" propeller of any pitch without over-heating. Or it may have to

drop additional pitch. The 12 x 4 propeller may not work, but a 12 x 3 might if such a thing is

actually available.

Also note that the load presented by any given propeller varies by manufacturer

and material the propeller is made from. One manufacturer's 6" pitch

propeller may be the same as a 7" pitch from another manufacturer.

I don't know how this happens. What I know is that there are different

methods of measuring pitch which makes no sense to me at all. But that's

how two manufacturers can make a 10-6 prop that don't actually have the same

pitch. Thus manufacturer one may call the other manufacturer's 10-6 prop a

10-5 by their way of measuring and the other manufacturer may call the first

manufacturer's 10-6 prop a 10-7 using their measurement system.

Standards are cool. Everyone should get on board with standard so we all

know what's going on. |

|

|

|

Variable Pitch Propellers

|

|

|

Speed

Vs. Pitch Speed

Vs. Pitch

In this example two different propellers will be mounted to the same engine. One

propeller has 4" of pitch and the other has 8" of pitch.

The propellers used present an identical load to the engine at all settings.

This is accomplished by lowering the diameter of the high pitch prop.

We have a perfect model aircraft having zero drag in a perfect world where

propellers are always 100% efficient and there is no such thing as drag.

The lowest reliable idle is 2,000 RPM. Each additional click of throttle

adds 500 RPM.

At 2,000 RPM we

calculate the following airspeeds:

4" Pitch = 7.8 MPH

8" Pitch = 15.2 MPH

Add one click of throttle (+500 RPM) and calculate the new airspeeds:

4" Pitch = 9.5 MPH

8" Pitch = 18.9 MPH

Speed increase:

4" Pitch = 1.7 MPH

8" Pitch = 3.7 MPH

Conclusion:

The lower pitch propeller provides finer speed control. |

As you can see, there is no single ideal propeller for the entire flight envelope.

When landing, for example, a finer pitch propeller will allow minute control

over the speed of the aircraft because small changes in RPM using the throttle

translate to small changes in speed.

See sidebar to the right for a

specific example.

A high pitch propeller

is desirable if you want an aircraft to fly very fast. It is easy to see

that any propeller selected will exclude desirable (and undesirable) properties

available with a prop having a different pitch.

This is why most sport pilots choose a middle of the road propeller. The

airplane won't achieve the highest possible speed that the high pitch would allow, nor

will it have the

best climb that a low pitch would provide. Instead the pilot is teased

with a little of both.

This is the reason variable pitch propellers were invented. A

variable pitch propeller allows the pilot (or an onboard flight system) to

change the pitch of the propeller to give the best thrust characteristics for

any given flight condition.

Even a variable pitch propeller is not perfect because the blade airfoil and the

shape of the blade will be ideal at only one RPM and one pitch.

Therefore these shapes are a compromise. Nevertheless, a variable pitch

prop is a marked improvement over fixed pitch versions.

The bad news is that only a handful of in-flight variable pitch propellers have

been marketed for model aircraft. They are always expensive and few people

purchase them. Therefore the propellers do not get developed and the range

of sizes from any given manufacturer is usually limited to approximately one.

I don't know if there's an in-flight variable pitch propeller available now or

not. The last one I was aware of was made by Kavan, a German

company.

My point for including this information is so you

can join me in brooding over our lack of nearly perfect propellers which you may

not have done if you didn't know that such a thing could be made.

Variable Pitch Propellers that are Non-Adjustable in Flight

Note that some propellers are marketed as being variable pitch which is true,

but misleading. The type of propeller I am talking about allow the blades

to be mounted in the hub at a variety of pitch angles. In practice the propeller is still a

fixed pitch propeller because the pitch can not be changed in flight. |

|

|

|

Number of Blades

Propellers have one, two, three or four blades. Single blade propellers

are counter-balanced and used on extremely high rpm racing motors. I've

never seen these sold anywhere and suspect they are built by the user. You

don't need to even think about these props unless you're building control line

speed aircraft. In fact, they may not even be used any more. I

haven't been paying attention.

In our realm, the most efficient propellers are two bladed. Because the

diameter of our propellers is so small, multiple blade propellers disturb the

air that the trailing blade is entering. Therefore, 3 and 4 blade

propellers are less efficient.

In general, the only time a 3 or 4 blade propeller should be used is for a more

scale appearance or when a smaller propeller disk is necessary.

For example, a scale, twin-engine aircraft may not be able to swing a 2-blade propeller

of a small enough diameter to clear the sides of the fuselage. A three and four

blade prop can be used here because it can be a smaller diameter and present the

same load on the engine.

For best performance with sport aircraft, stick to 2-blade propellers. |

|

|

|

Selecting and

Flight Testing Propellers

Everyone has an opinion regarding what material is best to make a propeller from

as well as their pet manufacturer. As I mentioned at the beginning of this

article, most manufacturer's propeller's work well and unless you're an expert

pilot, you probably won't be able to tell the difference between comparable

propellers from different manufacturers.

As far as I'm concerned the determining factor when selecting a propeller is

pitch. The diameter is selected after the pitch to put the proper load

on the engine. Often kit and plan manufacturers do not recommend a pitch

for their models. I've never understood this. I know what pitch

propeller is best for every plane I've designed and if I could ever complete a

set of plans the number would be on them.

When I am performing test flights of a new plane

(first several weeks) I take every prop the engine can swing and try each of

them.

Sometimes I find that none of the props I have give the plane the performance

I want, but I will have an idea of what prop to purchase.

A 6" pitch prop is a generally good starting point

for any engine .15 to .60 cubic inch. Smaller engines should start with a

2-5 pitch propeller. The smaller the engine, the lower the pitch for very

small engines (.061 and below).

I will perform the first test flight with a higher pitch propeller than what I

think is needed just to ensure the aircraft will have

enough airspeed. If I want the airplane to fly slower or climb better then

I will switch to lower pitch propellers when I am satisfied that the original

propeller provides more than enough airspeed.

If you want to get the most from your models, it is important to learn how to prop your plane correctly and

to learn to

use the throttle. There are too many pilots who think the engine is a

three-position switch: Off, Idle and Full-throttle with no settings in

between. |

|

|

|

Balancing a Propeller

An out of balance propeller or spinner can cause a lot of problems. Here's a

short, albeit incomplete list:

- Robs engine of power.

- Causes fuel foaming which can lean the engine causing it sag, quit or just

run inconsistently.

- Causes excessive vibration through the airframe potentially damaging it.

- Ditto for the onboard radio.

I don't bother balancing spinners. So far I have not had any real

problems due to this, but as I mentioned earlier, I don't wring out my

engines. If I did have a spinner that was noticeably out of balance I

would probably make a couple attempts at balancing it and if that did not work

I would just discard it unless it was particularly expensive.

Typically a spinner is balanced by drilling small indentations into the

backplate on the heavy side. It is a lot of trial and error and if your

results are anything like my attempts, then you will have pits all over the

backplate with no significant improvement in the balance. Obviously I'm

doing something wrong here.

There are a

variety of propeller balancers on the market. The worst of these are the

type that wedge a propeller between two cones on a shaft that is held between

your fingers. This is not real accurate, but it is better than nothing at

all and it is inexpensive. There are a

variety of propeller balancers on the market. The worst of these are the

type that wedge a propeller between two cones on a shaft that is held between

your fingers. This is not real accurate, but it is better than nothing at

all and it is inexpensive.

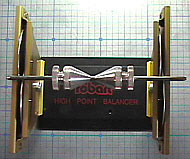

Robart makes an excellent propeller balancer called the High-Point balancer.

The High-Point has been very popular since it was first released because it is

accurate and easy to use. It also uses two cones and a shaft, but the

shaft rides on four large, free turning wheels. The idea is that the out

of balance condition is magnified due to the smaller shaft having a leverage

advantage — like a small gear turning a large gear.

The High-Point is not limited to aircraft propellers. Anything that is

has a hole in it can be balanced statically. This

includes spinners, helicopter rotor heads, flywheels, boat propellers, etc.

Before you attempt to balance a propeller, be sure to clean it. I wipe the

propeller down with alcohol or wash it in warm, soapy water.

Most propellers are close to being in balance when

you buy them so they should only need a small amount of work to bring them into

perfect balance. If the propeller is severely out of balance I return it

because too much material would have to be removed which would significantly

change the shape of the blade.

If one blade is heavier than the other, then the

usual method to bring the propeller into balance is to remove material from the

heavy blade using sandpaper.

Do not trim the tip of the heavy blade!

The

blade may balance statically, but it will not be balanced when the engine is

running do to unequal mass distribution. Some people say to remove

material from the face (front) of the prop and others say to remove it from the

back. I have done both and have never noticed a difference. Usually I

sand the face a little.

If you use wooden propellers and you sand them to bring them in balance, you may

also remove the fuel-proof coating. Obviously you don't want your

propellers to become fuel soaked.

Another way to balance a propeller is to spray a very light coat of clear

fuel-proof paint on the light blade. This is an exceptionally good method

because if you spray the paint evenly it distributes the added weight of the

paint evenly over the blade. It also will not change the shape as much as

sanding will.

The only drawback to this method is that you can't check the balance until the

paint has dried because you have to wait for the solvents in the paint to

evaporate. |

|

|

|

Mounting the Propeller

Back in the days when I flew control line combat

ships I learned that the best way to mount a propeller was in the dead stick

position.

That simply means the propeller is in the horizontal position (parallel to the

ground) when the engine is turned to where you can feel compression.

The

airflow will push the propeller into this position minimizing the chance of the

propeller contacting the ground and breaking if the engine dies in flight. Additionally, this is the

most convenient position for hand starting the engine.

(By the way, I never flew control line combat, but I

did like the ukie combat planes because they are wickedly maneuverable.)

Do not use a 4-way wrench to tighten a propeller nut!

Use an adjustable wrench (Crescent), open-end wrench or socket to

tighten propeller nuts. Four-way wrenches do not

allow enough leverage to torque the nut really tight. The propeller nut

provided with the engine and the crankshaft are both hardened steel. I have

never managed to strip either of these items and I am not even sure if I could if

I tried.

Check the propeller and spinner for tightness and damage as part of your

pre-flight inspection

I have seen a lot of props come loose as well

as some parting company with the engine on the ground or in the air.

In fact, somebody recently gave me a 91 four-stroke engine. I mounted the

engine

to my test stand and started it up at idle. I then moved behind the engine

and waited about 30 seconds for it to warm up.

When I advanced the throttle, the engine

backfired and threw the propeller and spinner. The propeller flew a good

75 feet at a high rate of speed. I would have been diced had I been in

front of it.

The $25.00 aluminum spinner spread out and will not fit back in the base.

It's ruined. |

|

|

|

Tracking the Propeller

Every once in a while you will buy a propeller that does not track properly.

Either the mounting hole is off-center or the hub is not square to the plane of

rotation. In either case, if the propeller is noticeably out of track you

should not use it.

For a propeller to track properly, both faces of the hub must be absolutely

parallel with the plane of rotation and the mounting hole must be centered and

perpendicular to the rotation plane.

It is easy to see if the prop is tracking correctly. Stand back for safety

and look at the propeller from the side and from the rear.

From the side, both tips should be clearly visible in the same line. If

you see two lines, then the hub is not square to the plane of rotation. You

can attempt to sand the hub square, but I would simply return the propeller

because it is defective.

When looking at the propeller from the back or the front, both tips should be in

the same circle. If you see two circles, then the mounting hole is off

center. Assuming you did not modify the propeller, then this too is a

defect and the propeller should be returned.

Videos of a propeller that tracks properly

(There's nothing exciting here. 99% of all propellers you buy will track

correctly)

|

Side Tracking

(0.6 Mb) |

Front Tracking

(0.6 Mb) |

The Bolly

web site that was recently brought to my attention. This site has a

great deal of information about propellers and additional theory. It is

worth taking a look.

|

|

|

|

|

|

|

|

Back to Model Aircraft Engines

Airfield Models Home |

|

|

|

Copyright © 2003 Paul K.

Johnson |

|

|

![]()