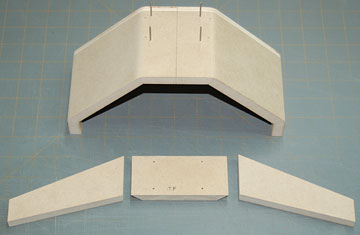

Making the Form

I drilled 1/16" holes in the landing gear blanks where the mounting screws will

go. These holes will be used to align the blanks on the form so matching

holes were drilled in the form.

I used the master landing gear pattern to locate the holes in the landing gear

blanks, form and the upper form clamp (next photo bottom center).

|

1/16"

music wire pins are used to align the blanks during the lay-up.

I used the same pattern to locate the pins as I used to drill the

landing gear blanks to ensure there was no chance of things not lining

up. In front of the form are MDF clamping blocks. Not

shown is a pair of blocks for the feet of the gear. All clamp

blocks should be slightly oversize all around.

The holes in the center clamp block are one drill size larger to

ensure it slides over the pins easily. |

|

Thin drop cloth material is the mold release. It is

pulled taut around the form and secured with tape. The clamp

blocks received the same treatment. The form is ready to use.

The four 1/16" pins are cut long enough to extend above the center clamp

block when the whole works is together. That allows the option of

removing the pins before the epoxy cures. |

|

![]()